Fast Growing Commercial Forests

Irelands climate supports fast growing forests, Pine/Sitka 20-30 years & Willow 4 -10 years, due to its mild Atlantic climate. There is also a substantial amount of underutilized Biomass & Forest harvest residues that currently is not realising a return to farmers but meets the supply requirements of Carbon Soles Biomass Woodchip Gasification plants.

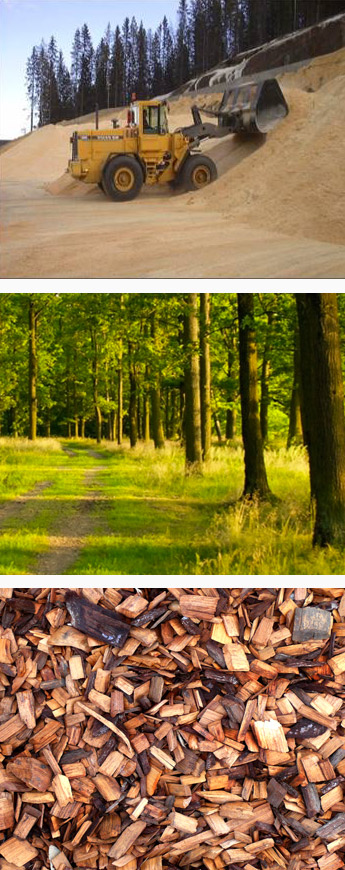

This project will remove excess woody forest material in order to provide renewable energy, thereby resulting in reduced fire risk, watershed protection, air quality benefits, greenhouse gas benefits, local jobs, and forest ecosystem protection.

Private Forestry owners mainly rely on market prices for

- Saw Log timber followed by Pallet wood, Stake wood and pulp wood

- Pulp wood is largely sold to board mills and is used for small grate type biomass boilers

- The vast majority of Forest Waste and Harvest Residues is not suitable for small wood chip boilers and is left to rot on the ground. When gathered and piled on harvest, it will increase returns to the farmer.

- On average 10 Hectares of clear fell produces 700 ton of harvest residues (branches, tops, stumps).

- When clear fell takes place the farmer now has an immediate outlet for harvest residues resulting in a reduction in the time to replant, reducing the impact of beetle larvae on new plantations and increasing the return per hectare.

Plant Locations

Carbon Sole Plants were purposely located central to the highest density forested areas, with an objective of meeting each Plants biomass requirements from within 100km radius to limit haulage costs and the supply chain carbon footprint.

Each Plant requires 280,000MWh of Biomass per annum, approximately 120,000 green wet tonnes that is dried down to 70,000 dry tonnes.

Woodchip Gasification

Carbon Soles assessment of available biomass resources has resulted in the company commissioning a woodchip gasification system that can effectively and cleanly process harvest residues and forest waste such as forest thinning’s, tree tops, branches, stumps and pulp wood supplied as wood chips.

The process involves essentially ‘baking’ the woodchip, thermally cracking it in an enclosed system to produce a rich syngas, a biogas, that is further upgraded and distributed off-site, as it is produced.